INJECTION MOLD PARTS

PREMIER MANUFACTURER AND SUPPLIER

Global supplier of quality hot runner components. We offer the highest-quality nozzle tips, Vespel® insulators as well as retainers and housings. We use cutting-edge technology to meet today's demands for an innovative future. Together, we create a unmatched customer experience with unsurpassed attention to detail.

INJECTION MOLD PARTS AND SERVICES

HOT RUNNER SOLUTIONS

At Hotrunner Technologies Inc., we are innovative and experienced leaders with over 35 years of knowledge in the design and manufacturing process of hot runner components. We are constantly evolving as global technology changes and progresses to meet our clients' needs. We provide our valued customers with a complete solution to their hot runner component requirements. HTI is the best source for cost-effective OEM parts.

Our dynamic approach to hot runner solutions begins with understanding our customers needs. From start to finish, we design and create superior quality parts. The results are fully integrated solutions to meet today's demands, for tomorrow.

SINCE 1987

OUR PRODUCTS

WHAT WE OFFER

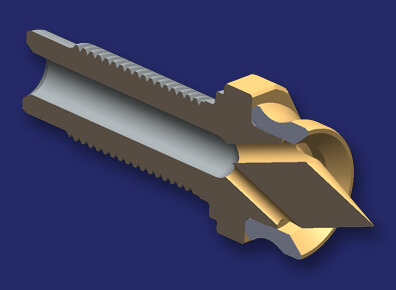

Our superior crafted products are engineered using our modern, state-of-the-art design and manufacturing processes. The finished products are industry-proven to stand up to the service requirements of today's market. Our diverse line of includes carbide tipped nozzles, retainers and housings to provide unique solutions to complex problems. With our focus on injection molding complications, we have the ability to solve complex molding issues.

NOZZLE TIPS

Our nozzle tips use advanced performance techniques in a large range of applications. We deliver a vast selection of nozzle tips including state-of-the-art TZM and carbide tipped nozzles. From high-precision components to stress-free flow designs, our nozzle tips have the capability to suit any application from any OEM.

VESPEL INSULATORS

We only use authentic DuPont Vespel® materials to guarantee you receive the same quality used in your original hot runner system. The high-performance parts provide maximum strength, durability, elongation and the best thermal insulation values. The wear-resistant nature of Vespel® materials give you confidence and security in your hot runners' capabilities.

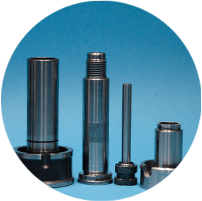

RETAINERS

Our retainers and seal nuts have been redesigned to surpass original OEM specifications. Going above and beyond OEM specifications allows us to provide our customers with a product that can stand up to the high demanding environments. Our retainers and seal nuts ensure any project can be accomplished with the utmost precision.

HOUSINGS

We offer housing solutions to match your material specifications. There are no limitations to availability. We can manufacture components to any specification you may need. This pivotal point is what makes HTI the best source for all your hot runner solutions.

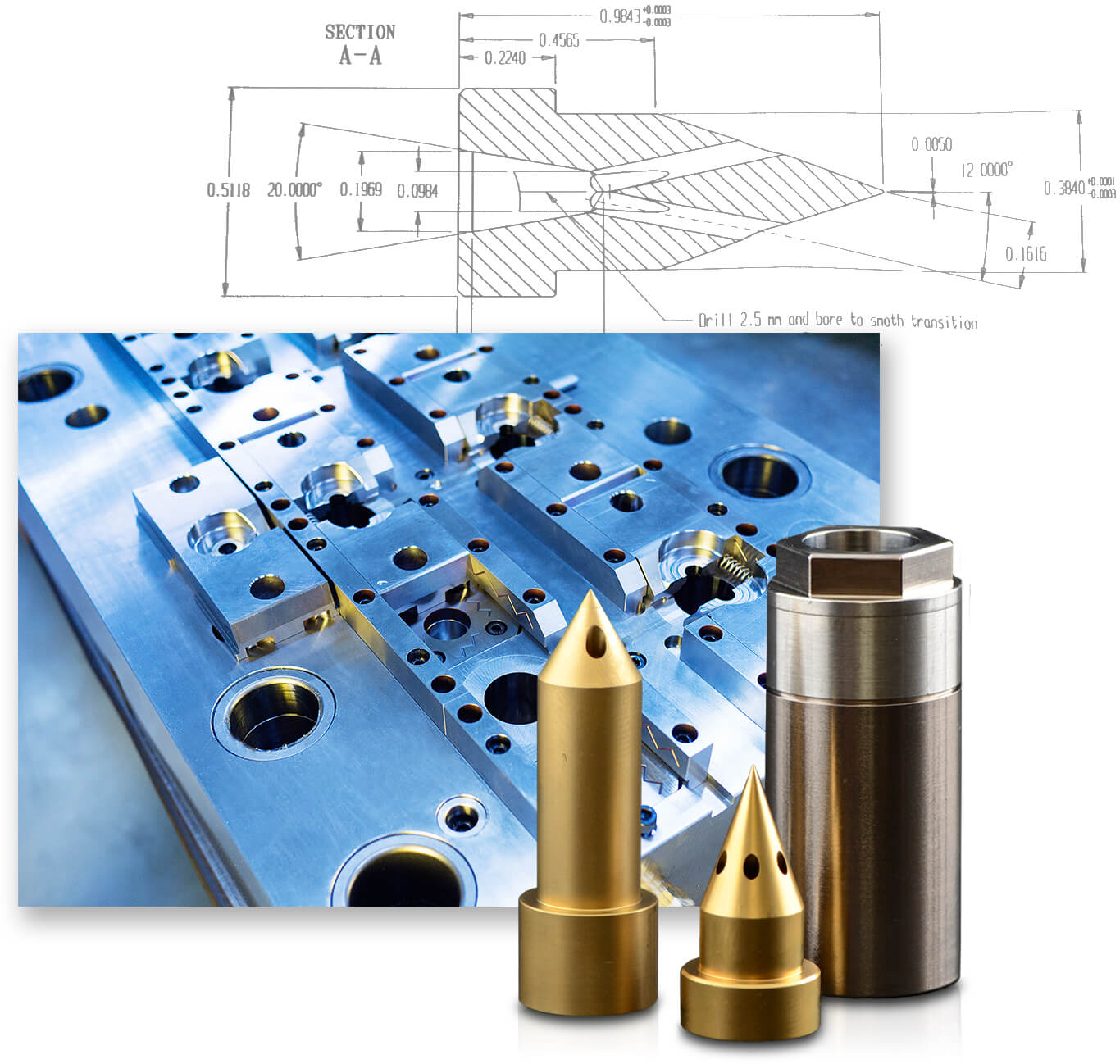

ENGINEERING OF INJECTION MOLD PARTS

HOT RUNNER SOLUTIONS

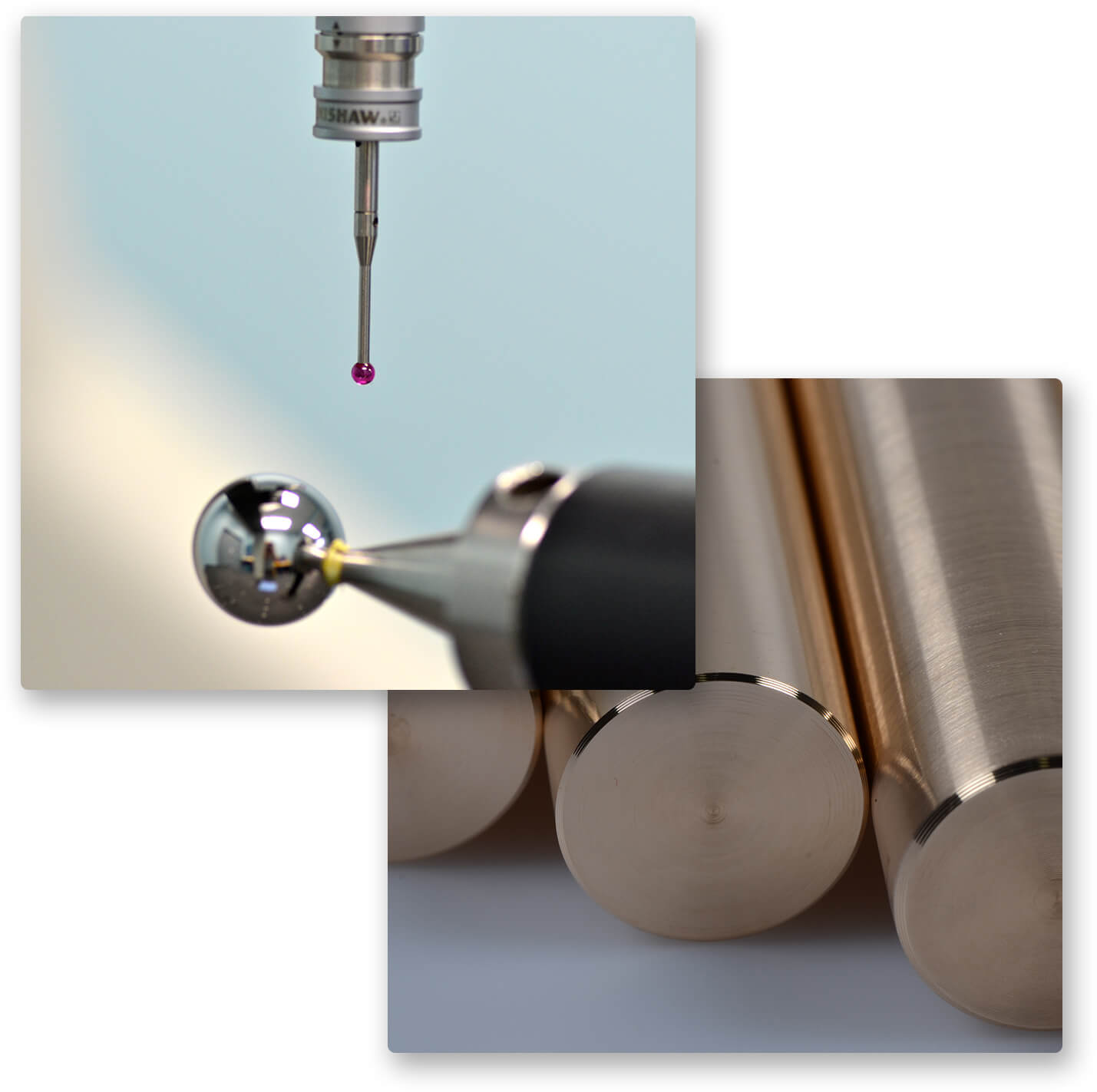

Our specialties go beyond injection molding services. We don't just offer the manufacturing of top-quality parts for injection mold systems, we also offer engineering services. We use the newest and latest computer software to produce, engineer or reverse engineer parts for hot runner systems and applications. The quality of our products is unmatched. We guarantee to meet or exceed OEM specifications in order to help deliver superior performance.

SOLVING GATE ISSUES

Any injection mold requires a gate to allow the molten plastic to fill the mold cavity. With our years of experience and expertise, we're able to make sure any injection molding process has the smallest gate visible. Our engineering is so precise, that we are able to minimize the gate vestige, in turn increasing productivity in the mold.

REVERSE ENGINEERING

Our capabilities and mastery of reverse engineering hot runner parts allows us to create top-quality injection mold parts which are the same quality, if not better than OEM parts. Whether you need redesigned or spare mold parts, we've got you covered, even if they're obsolete and no longer manufactured by OEM.

EXPERIENCE HTI QUALITY

REASONS TO WORK WITH US

PREMIER, GLOBAL SUPPLIER OF INJECTION MOLD PARTS AND SERVICES

SETTING QUALITY STANDARDS AS

“Quality is ingrained into everything we do at HTI. Our commitment to quality involves providing industry-proven components, unmatched service and integrating new technologies to surpass customer expectations.”

At HTI, we pride ourselves with the ability to produce OEM quality parts, whether it is original or custom design is required. We use sophisticated measuring instruments to reverse engineer your part to determine OEM specifications. We understand component design intent including component form, fit, and function before undergoing the manufacturing processes. These high-precision techniques allow the utmost attention-to-detail in engineering your part.

Quality begins working with high-standard materials. Our components are manufactured to ensure longevity and efficiency. We only use premium copper, both Beryllium and Beryllium-free for manufacturing nozzle tips and Dupont™ Vespel® material in our insulators. By using the best materials in the industry, we are able to provide excellent mechanical properties.

We manufacture all of our components on the most advanced state-of-the-art CNC machine tools to ensure both precision and unsurpassed quality. We use sophisticated multi-axis machine tools to provide total solutions in the manufacturing of complex parts. Having the flexibility to manufacture various high-precision components gives us the opportunity to provide enhanced service and support to our valued customers' injection molding needs.

Standing firmly behind our products, we believe our coatings are vital to creating quality parts. Our coated nozzle tips can serve even the most complex applications and are resistant to particle erosion at high temperatures. We stand out from the competition by offering cutting-edge plating and coating technologies. We are consistently looking for applications in new technologies to provide coatings with low coefficient of friction and pride ourselves in offering the best in Advanced Nickel plating and PVD coatings from OEM certified vendors.